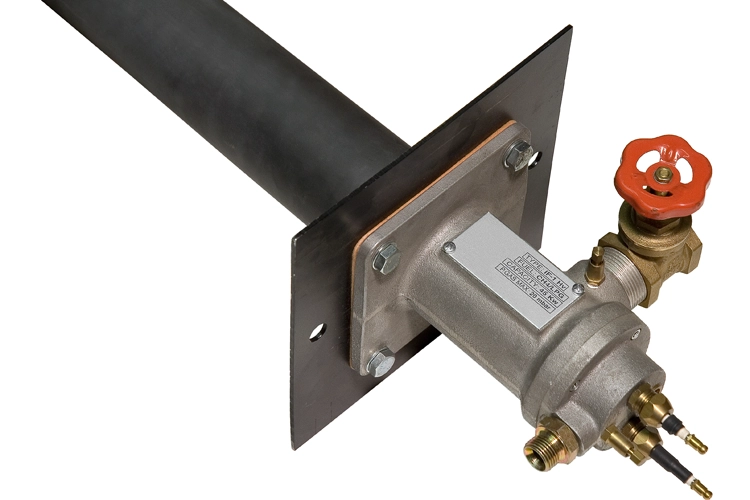

Itek designs and manufactures medium and high-speed burners, M series. The burners are equipped with a spiral mixing nozzle to promote perfect mixing of the gas and combustion air at the ignition point. Each burner is equipped with a double pilot, gas and air valves, and a dynamic pressure tap, and can be supplied in different designs and with cones of different lengths and diameters so that it can be installed on any kiln. The cone is made of silicon carbide and, thanks to the different sizes available, allows for variable flame speeds and lengths, depending on the technological characteristics of the product to be treated.

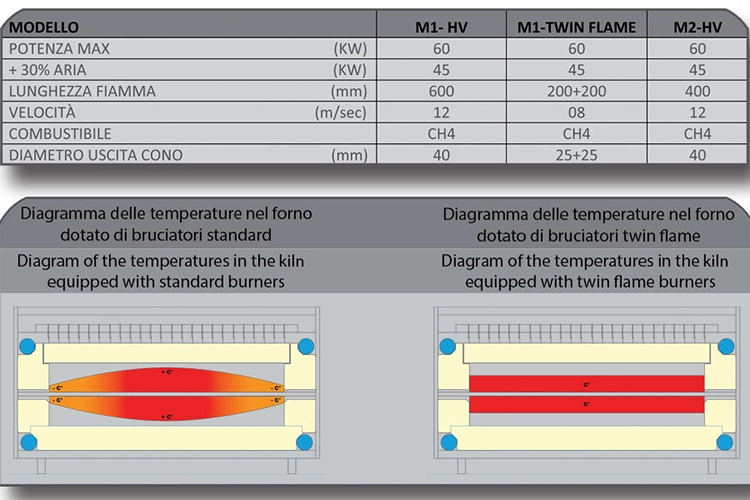

The M1 series burners can be supplied with a special silicon carbide cone, called twin flame, in order to eliminate problems arising from uneven temperatures in the kiln, namely dimensional variation of the tiles (calibre), incorrect flatness, and differences in tone. As shown in the attached diagram, and with reference to a typical cooking section, the temperature at the center of the channel is higher than that found at the walls. The installation of the twin flame burner allows the combustion products to be distributed along the walls of the furnace in order to even out the internal temperatures of the furnace cross-section.