Kiln designed for laboratory testing of materials and glazes up to 1220°C

The various exclusive design solutions introduced make it possible to reproduce the same operating conditions and atmosphere of a normal production kiln during laboratory tests:

The gas burner equipment and brick insulation create the same atmosphere inside the kiln chamber as in a standard burner kiln. The kiln zones are divided into preheating, firing, rapid cooling, and final cooling, which are the same as in a standard roller kiln.

The self-regulating zones, one for preheating, two for cooking, and one for rapid cooling, allow the cooking curves to be reproduced accurately. The solutions adopted for the smoke chimney and hot air extraction during cooling allow the extraction to be adjusted according to the cooking curve. The 48 mm roller pitch allows small formats to be cooked.

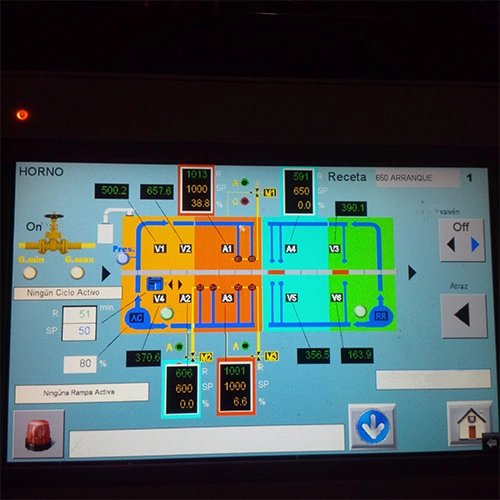

Separate power panel and control panel, with SMARTLAB supervision system.

LAB42 complies with UNI EN 746-1 and UNI EN 746-2 and GOST regulations.

TECHNICAL DATA:

-

- Max. tile size 400×400 mm

- Max. tile size 400×400 mm

-

- Minimum tile size 100×100 mm

- Minimum tile size 100×100 mm

-

- Reference cycle 60 min – Productivity 1.6 m²/hour

- Reference cycle 60 min – Productivity 1.6 m²/hour

-

- Total length 4200 mm

- Total length 4200 mm

-

- Useful loading mouth width 400 mm

- Useful loading mouth width 400 mm

-

- Payload height 50 mm

- Payload height 50 mm

-

- Roller center distance 48.84 mm

- Roller center distance 48.84 mm

-

- Cooking cycle adjustable from 30 to 150 minutes via inverter

- Cooking cycle adjustable from 30 to 150 minutes via inverter

-

- Maximum operating temperature 1220°C

- Maximum operating temperature 1220°C

-

- Natural gas fuel CH4

- Burners installed 6

- Self-regulating cooking zones 3

- Self-regulating cooling zones 1

- Fans installed 3