Itek company designs and manufactures burners, medium and high speed type, M series. The burners are equipped with spiral geometry mixing nozzle, to allow the perfect mixing of the gas and the combustion air in the ignition point. Each burner is equipped with double electrode, with air and gas valves and pressure intake, and it can be supplied in various constructive versions and with cones in different lengths and diameters to allow the installation on any type of various kilns. The cone is in silicon carbide and, thanks to the various available dimensions, it is possible to get different speed of the gases and variable flame lengths, in accordance with the technological features of the material to be fired.

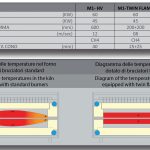

The M1 series burners can be equipped with a special cone in silicon carbide, identified as twin flame cone, in order to eliminate the defects due to a non-uniform temperature inside the kiln, that is the size variation, the incorrect planarity and the difference in tones. As shown in the enclosed diagrams, and with reference to a typical kiln sectional view, the temperature in the center is higher compared with the temperature at the wall. By installing the twin flame burners, the combustion gases will be diverted towards the walls of the kiln, so as to uniform the inner temperatures in the kiln cross section.